High-efficiency reheat technology helps Hunan Shaofeng Southern Cement Co., Ltd. to save energy and reduce carbon

Release time:

2023-05-10

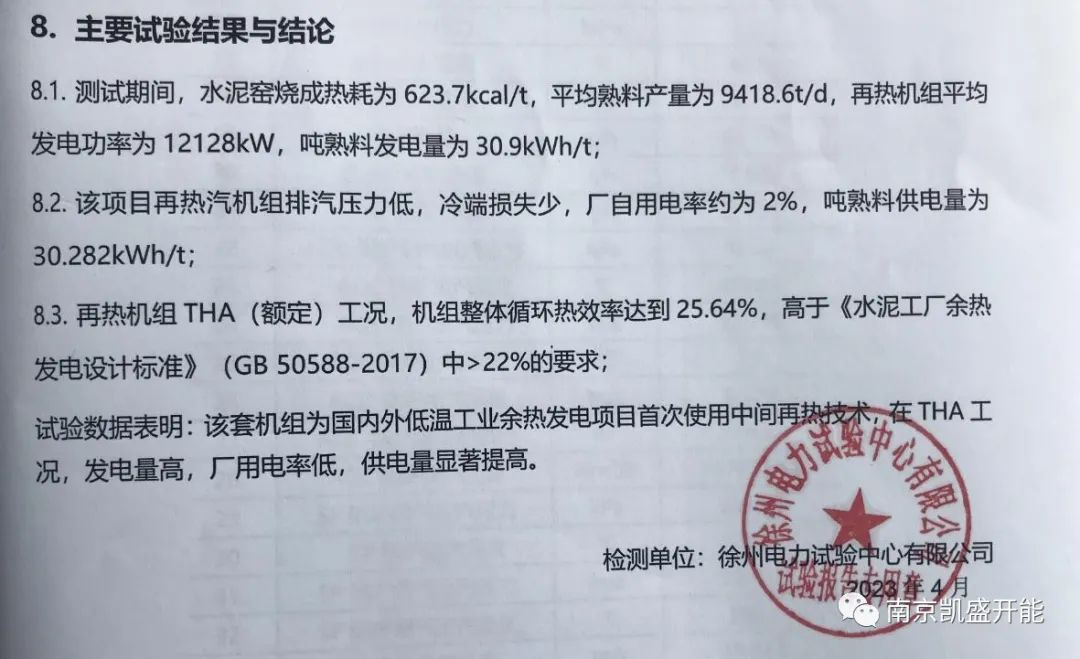

Recently, the performance test, conducted by Xuzhou Electric Power Test Center, of the low-temperature waste heat high-efficiency reheat power generation project in Shaofeng, Hunan, which was implemented by the general contract of Nanjing Kesen Kenen. the heat consumption of kiln system was 623.7kcal/kg.cl, the average clinker output was 9418.6t/d, the average power generation of the reheating unit was 12128kW, and the power generation per ton of clinker was 30.9kWh/t; the power consumption rate of the plant was about 2%, the power supply per ton of clinker is 30.282kWh/t, and the overall cycle thermal efficiency of the unit reached 25.64%.

Figure 1 The site map of Hunan Shaofeng waste heat power generation project

Figure 2 Hunan Shaofeng waste heat power generation project performance test report

The project was officially put into operation in July 2022, and passed the 72-hour performance assessment from September 10th to 12th. During the assessment period: the clinker output was 10420 t/d, the average power generation power reached 13004kW, and the power generation index per ton of clinker reached 29.95kWh/t.cl.

The 72-hour performance assessment results and the performance test results from Xuzhou Electric Power Test Center all show that the high-efficiency reheat power generation technology of the low-temperature waste heat can operate safely, continuously and stably, and has the outstanding features of high power generation, low power self-consumption and high power supply.

In order to improve NKK's competitiveness, the project adopts three innovative technologies: this project is the first to use steam turbine intermediate reheating technology for low-grade industrial waste heat power generation projects at home and abroad; based on the technology of original inverted integrated second-generation AQC boiler, the third-generation AQC boiler with side inlet air has been successfully developed; the intelligent control 2.0 system has been adopted to realize the "one-button start", "unattended", "cold-end optimization" and "power plant optimization" and many other Intelligent manufacturing function; meanwhile, details such as heat preservation and vacuum system have been continuously optimized. The project has achieved great success, and the technology is worth vigorous promotion.

Due to the successful commissioning of this project, the high-efficiency reheat power generation technology is being further promoted and applied in NKK's Xiang Northwest project, Hunan Jinlei South project and Bijie Southwest cement waste heat power generation project, providing a strong core technology support for NKK's sustainable development.

Related news

+86 025-68082504

+86 025-68082504 marketing@njkskn.com

marketing@njkskn.com

Messages

Messages