Xuzhou Longshan Cement's Waste Heat To Power (WHP) System Technological Upgrade Project Successfully Connected to the Grid for Power Generation on First Attempt

Release time:

2024-11-22

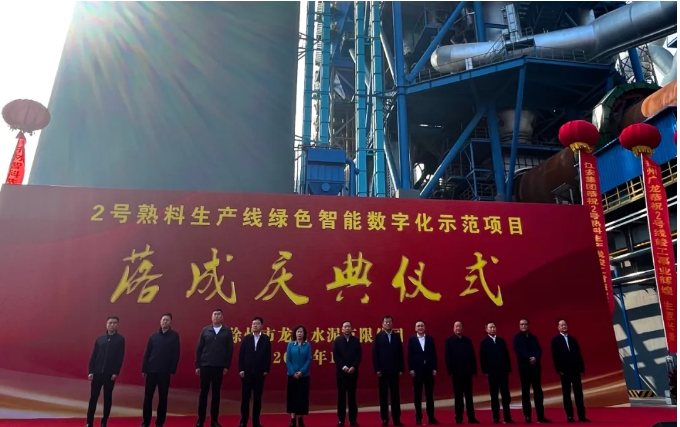

At 00:48 on November 9, 2024, the high-efficiency reheat-based WHP system technological upgrade project for the green intelligent digital energy-saving transformation of No. 2 clinker line at Xuzhou Longshan Cement Co., Ltd., constructed by Nanjing Kesen Kenen Environment & Energy Co., Ltd. ("Kesen Kenen"), successfully connected to the grid and generated power on the first attempt.

Located in Jiawang District, Xuzhou City, Jiangsu Province, this project is the world's first to upgrade a 5,000 t/d clinker production line from a five-stage to a seven-stage preheater. Upon completion, it will reduce the standard coal consumption per ton of clinker from 106 kilograms to 88 kilograms.

Considering the characteristics of upgrading the cement line to a seven-stage preheater, our company employed the independently-developed high-efficiency reheat technology for waste heat recovery and power generation and residual air recirculation technology for the technological transformation, further enhancing WHP efficiency. The project transformed the original steam turbine into a high-efficiency reheat turbine unit, saving on engineering investment. The on-site shutdown lasted only 70 days, reducing the construction period. Compared to previous units, the power output increased by approximately 10%, allowing the recovery of project investment within 1.5 to 2.5 years and bringing significant economic and social benefits to the owner.

Throughout the project's construction, all our employees worked together, rose to challenges, and overcame the difficulties of a prolonged turbine modification period and a tight installation schedule. They also surmounted adverse factors such as limited space and variable weather conditions, ensuring quality and timely completion. The project successfully connected to the grid and generated power on the first attempt.

The grid-connected power generation of this project signifies the successful realization of China's first transformation of a conventional cement kiln WHP steam turbine into a high-efficiency reheat unit. This achievement is another milestone embodying Kesen Kenen's mission of "achieving low carbon and high efficiency, realizing green dreams, and creating maximum value for customers."

Related news

+86 025-68082504

+86 025-68082504 marketing@njkskn.com

marketing@njkskn.com

Messages

Messages